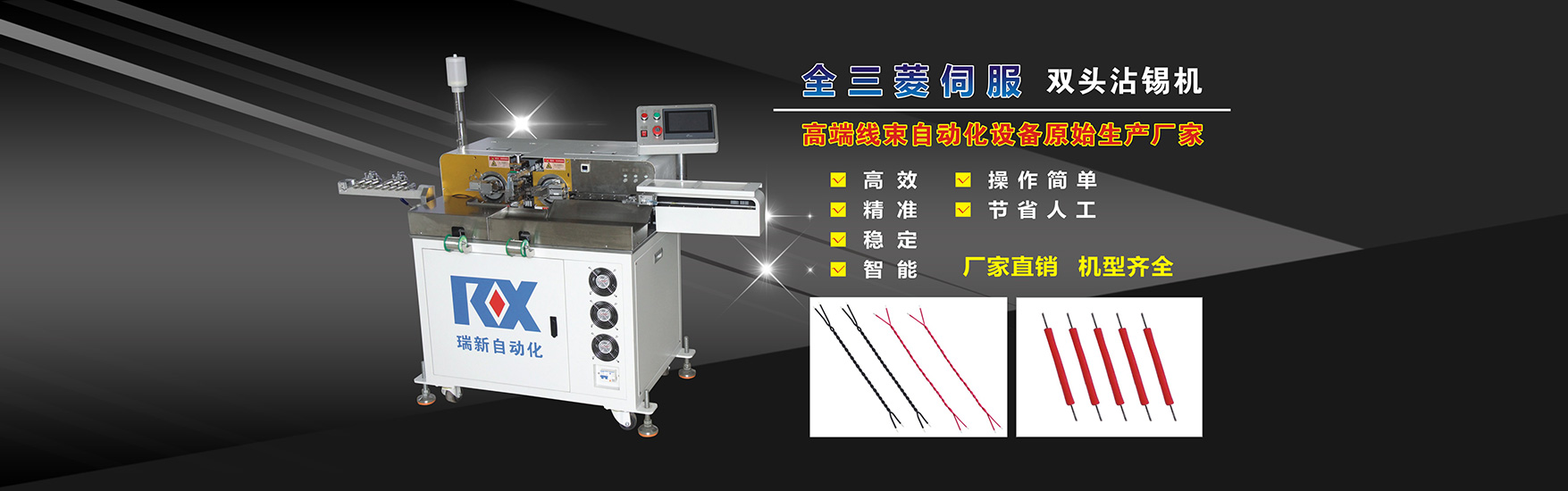

As long as it is mechanical equipment, there will always be problems, no matter what machinery, so the tin dipping machine | automatic tin dipping machine | full-automatic tin dipping machine | automatic tin dipping machine manufacturer | Ruixin automation is here to summarize and solve the problems of single head full-automatic terminal machine, so as not to make everyone have no countermeasures in case of problems.

Problem 1: the full-automatic terminal machine cannot start or stops suddenly during operation

Solution 1: check whether the current input is normal

Solution 2: check whether the total number of settings is now qualified. If it is qualified, power off and start again after re setting

Solution 3: check whether there is wire or a part stuck

Solution 4: check whether there is signal link at the single head of the automatic terminal machine, or the machine is not pressed due to power connection

Problem 2. The length of electronic wire is inconsistent

Reason 1: the wire feeding wheel is pressed too tightly or too loose

Solution: adjust the gap between the two wheels by micro conditions of the first roller so that the wire is not flattened and too loose, resulting in slipping

Reason 2: the straightener is too tight or too loose

Solution: adjust the straightener so that it can be sent out smoothly

Reason 3: wear of tangent crossing or cutting edge

Solution: replace with a new cutter

Problem 3: too much noise

Reason 1: loose screws

Solution 1: fastening screws and other spare parts.

Reason 2: there are foreign matters on the machine

Solution 2: it may be that other items are stored on the terminal machine or inside, resulting in a sensation when the machine works. When the machine and items collide and make a sound, find the items and remove them.

Reason 3: resonance principle

Solution 3: when the vibration reaches the natural frequency of an object, resonance may occur. When resonance occurs, the possible noise will be very obvious. Try to fine tune the parameters to prevent reaching the natural frequency.

Problem 4. Uneven exposed copper wire of pressed terminal

Solution 1: check whether the grab swing arm conduit corresponds to the wire

Solution 2: check whether the machine crossing is relatively straight with the swing arm conduit

Solution 3: check whether the auxiliary pressure block of the machine is loose

Solution 4: check whether the interval between the machine and the automaton has changed

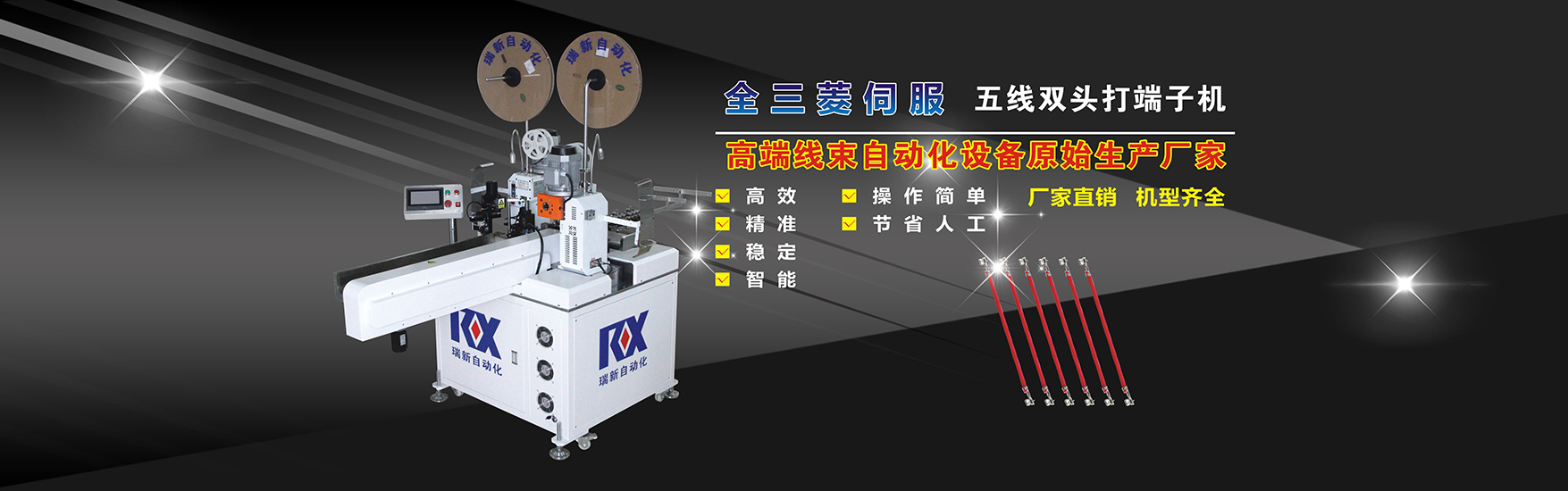

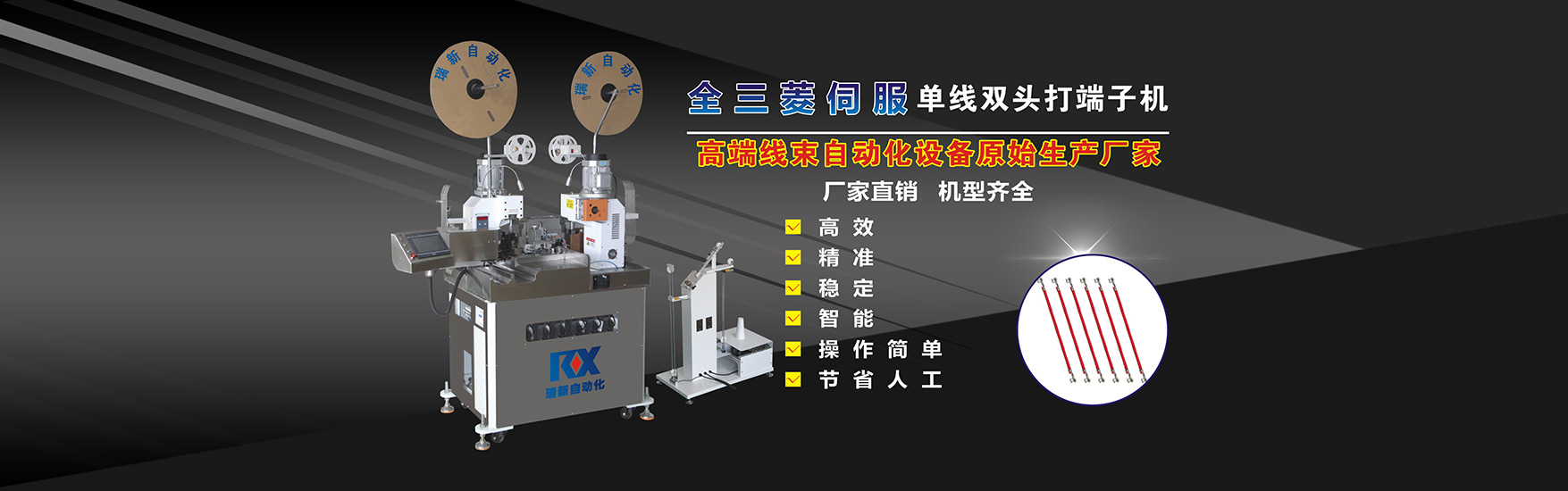

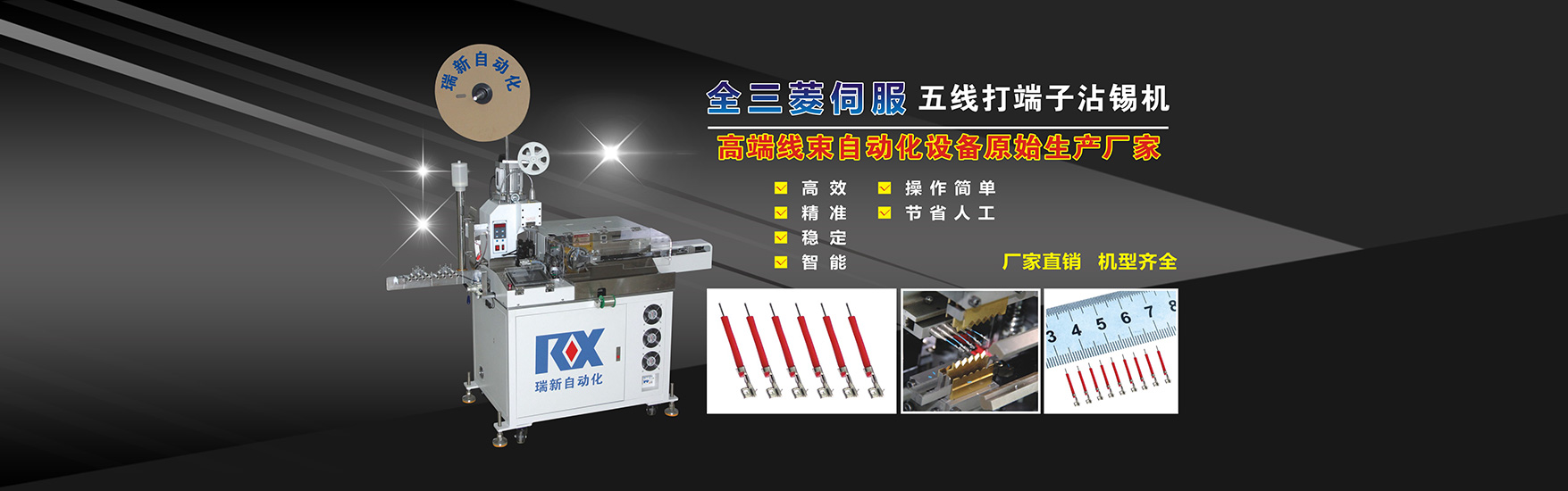

Although the full-automatic single head terminal machine is a little simpler than the full-automatic double head terminal machine, its central principle is the same, so the solutions to common problems are roughly the same. After reading this article, if there are problems, you will have a certain knowledge reserve to solve the problems. If other problems cannot be solved, you can consult us, Ruixin automation is a high-tech enterprise specializing in the R & D and manufacturing of automatic harness end processing equipment. The company is located in a prefecture level city under the jurisdiction of economically developed Guangdong Province of China. It has the reputation of "world factory". It is the beginning of modern Chinese history and Dongguan, one of the "Four Tigers of Guangdong". After decades of development and technical precipitation, the company has domestic advanced production equipment and perfect management system, and has won the trust and support of many customers at home and abroad with excellence quality and good reputation!