The impact force of the full-automatic terminal machine is very large, so we should pay more attention during operation, do not touch its running track during its operation to avoid collision, and turn off the power supply at the first time in case of abnormal conditions. The correct operation process of full-automatic terminal machine is as follows:

1. Turn on the power switch of the automatic terminal machine, and the power indicator is on.

2. Pay attention to whether there is any significant abnormal noise inside and outside the machine. If the operation is suspended, ask the machine maintenance personnel to determine whether it needs to be repaired.

3. Knife selection and installation: it is operated by designated personnel. Before installing the knife, it is necessary to manually compare whether the selected blade is matched, and the knife can be installed only after the comparison is correct. After installing the knife, it is necessary to use manual test. First, turn off the power supply of the terminal machine, press the down button, and use a special wrench to swing the master-slave driving wheel, so that the stamping stroke of the strip stripping and terminal punching machine is large, if the hand does not move, Consider whether the pressure is too high or other problems, and check and debug to OK. Before operation, check each locking screw and confirm that it is not loose.

4. Loading: install the required terminal, use the hexagonal wrench to adjust the feeding pressing plate, so that the terminal can pass easily, and visually check whether the feeding direction is appropriate. If not, adjust it, use the hexagonal wrench to loosen the locking screw of the feeder, screw the conditioning rod to adjust it until it reaches the state, then lock the locking screw of the feeder and start the operation.

5. Test the tension: after the adjustment is OK, take the waste wire rod for trial beating and conduct the tension test. See the comparison table of tension test for the main reference values. The specific operation methods are as follows: press the zero key of tension test to zero, clamp the terminal wire rod to be tested, and conduct the test. If the measured tension is not within the specification range, ask the machine maintenance personnel to adjust it from scratch until it reaches the specification value.

6. 10 pcs of trial production shall be sent to IPQC for first article recognition and inspection. Batch production can be carried out only after it is OK. During the production process, the operator is necessary to self check whether the terminals have defects such as glue wrapping and hanging neck, and conduct terminal tension test every 1 hour.

7. After the completion of production, sort out the finished products and defective products, and clean the environment around the full-automatic terminal machine.

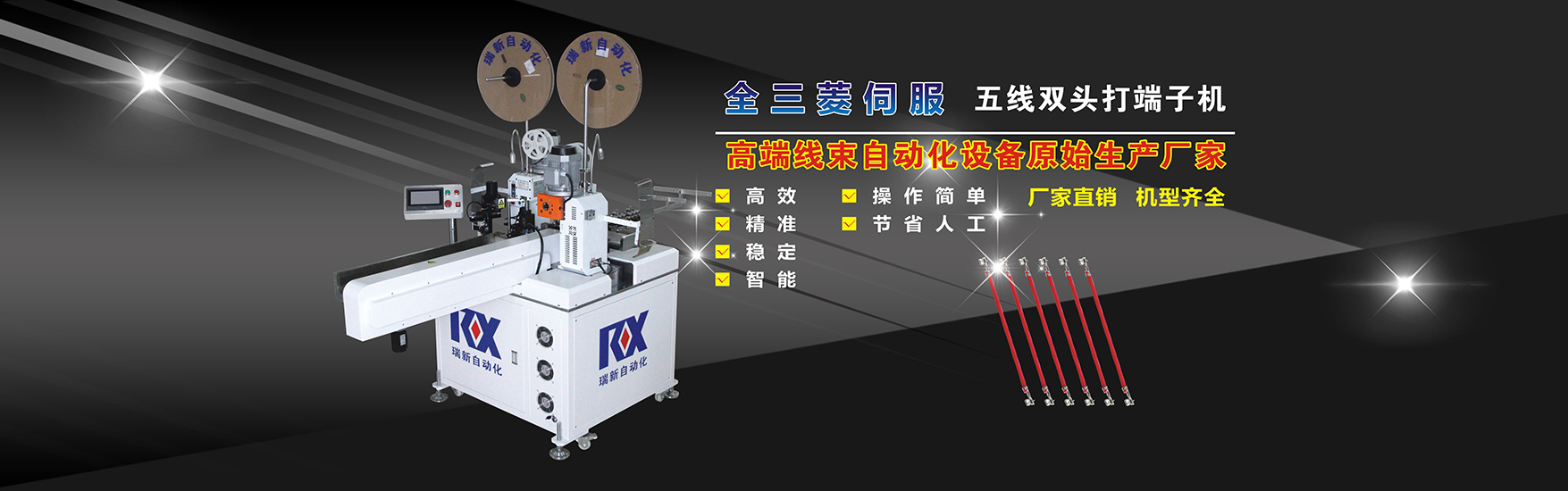

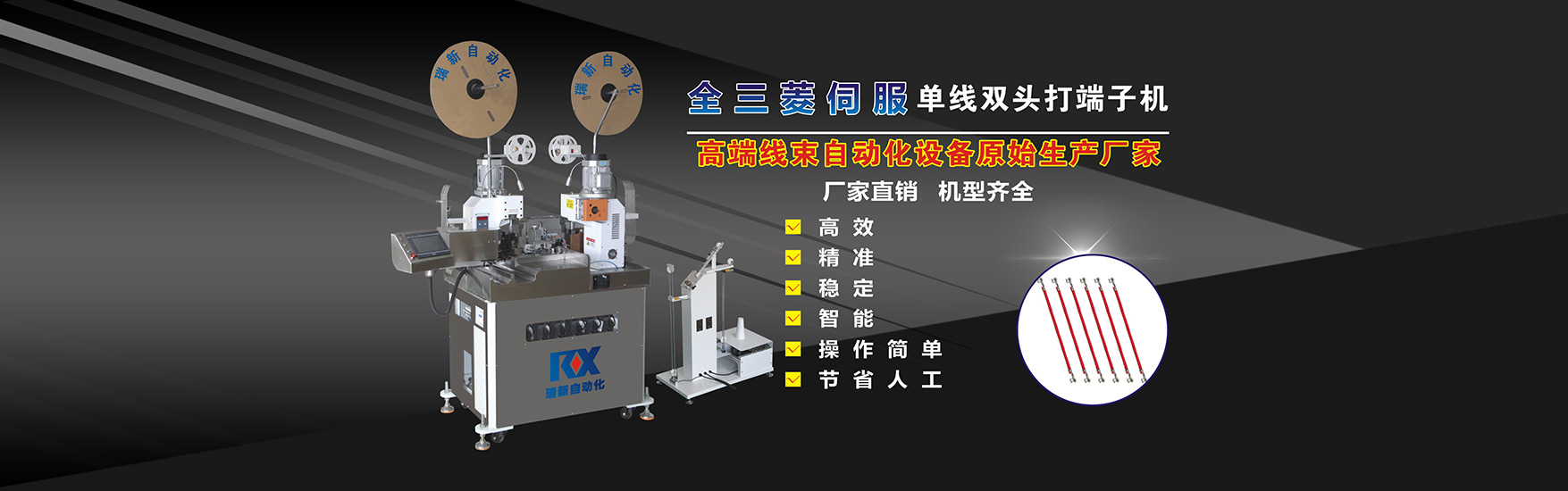

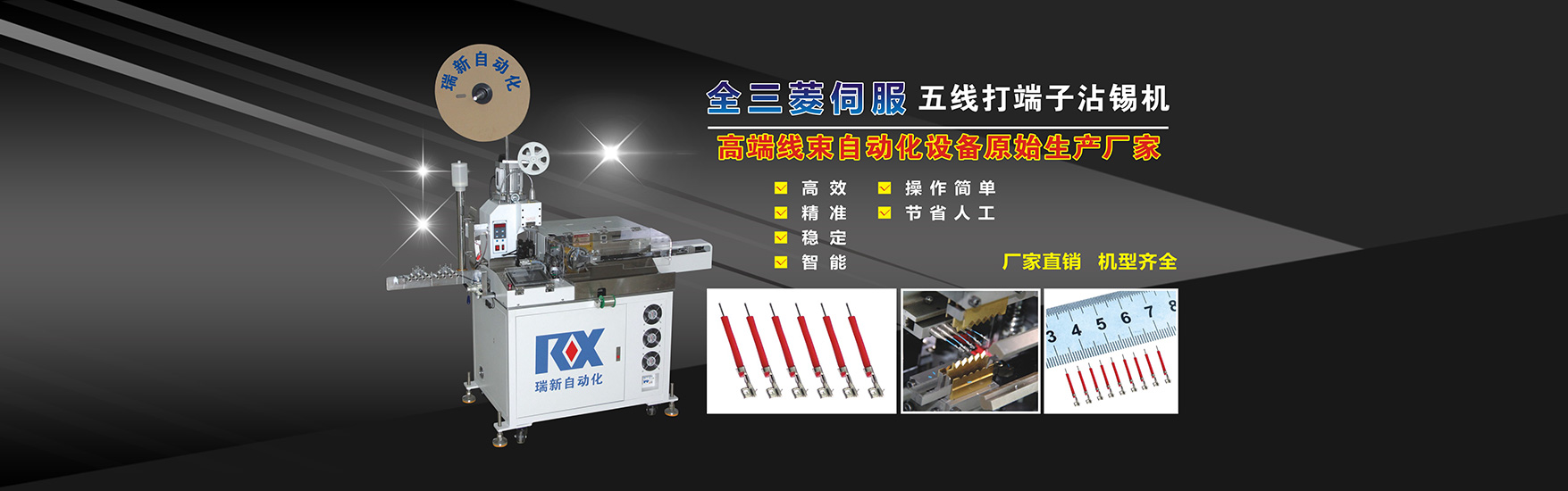

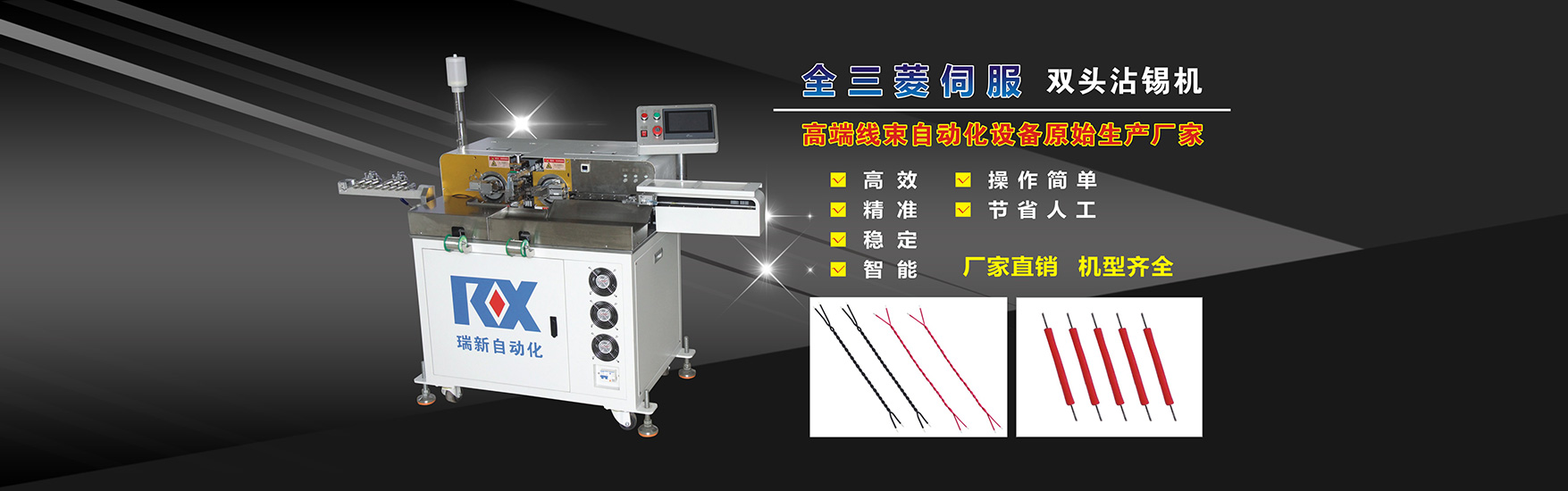

Learn more about terminal machine automatic terminal machine full automatic terminal machine manufacturer Ruixin automation is a high-tech enterprise specializing in R & D and manufacturing automatic harness end processing equipment. The company is located in a prefecture level city under the jurisdiction of economically developed Guangdong Province of China. It has the reputation of "world factory". It is the beginning of modern Chinese history and Dongguan, one of the "Four Tigers of Guangdong". After decades of development and technical precipitation, the company has domestic advanced production equipment and perfect management system, and has won the trust and support of many customers at home and abroad with excellence quality and good reputation.