As the main equipment of wire harness production industry, automatic terminal machine is very useful in wire harness production. Therefore, in the process of using the equipment, all users should pay more attention to all matters. Only by paying attention to these problems and preventing accidents can we make better use of the product. What should we pay attention to? The following is a detailed description of how to operate the fully automatic terminal machine safely.

Precautions for safe operation of automatic terminal machine

1. Before starting

We must pay attention to the preparations before carrying out the operation of the fully automatic terminal machine. Before use, you need to check the equipment in detail to see whether there are any loose parts inside, and whether all aspects of the equipment are in normal condition only under normal conditions. It is very important to start using the equipment and must be paid attention to.

2. In operation

In the actual operation of automatic terminal machine, we still need to further understand some practical operation solutions. Well, you can specify a good plan and plan according to your actual use requirements before actual operation, which will also bring greater help to users. If you need to leave work during operation, you must turn off the power before leaving. When replacing terminals, the power supply must be disconnected before the replacement operation. It is strictly forbidden to replace the machine during operation. If there is a terminal stuck in the die, it must be removed with scissors or pickaxe pin before continuing.

3. More details

Do not assign personnel to debug or disassemble the machine without permission. During operation, the power supply of the machine is not disconnected. It is forbidden to enter the punching range with fingers or any part of the body to avoid accidents.

It is necessary to understand some common problems of fully automatic terminal machine. Only in this way can we better deal with some emergencies that may occur during the use of the equipment and achieve better results.

Safety operation steps of fully automatic terminal machine

1. On

Turn on the power switch of the terminal and the power indicator lights up.

2. Pay attention to abnormal sound

Pay attention to whether there is obvious abnormal noise inside and outside the machine. If there is any suspension, ask the mechanic to determine whether it needs to be repaired.

3. Install the paper cutter

Select the knife and install it by the designated person. Before installing the knife, you must manually compare the selected blades for matching. After the comparison is correct, the knife can be installed. After the knife is installed, the manual test must be used. First, turn off the power of the terminal. Press the die adjustment button and use a special sheet to assist the master and slave wheels to maximize the stamping stroke of the terminal. If the hand does not shake, consider whether the pressure is too high or other problems. Check the debugging type to determine. Before operation, check the locking screw and make sure it is not loose.

4. Loading

Install the terminal to be perforated, adjust the paper feeding pressing plate with the hexagonal wrench so that the terminal can pass easily, visually check whether the paper feeding position is appropriate, if not, please adjust it, loosen the locking screw of the paper feeder with the hexagonal wrench, turn the adjusting screw for adjustment until it reaches the state, and then tighten the locking screw of the paper feeder to start the operation.

5. Test tension

After the adjusting machine is normal, take down the waste metal wire and conduct tensile test. The main reference values are in the "tensile test comparison table". The specific operation methods are as follows. Press the zero button of the tensile test to adjust it to zero. The wires are clamped and tested. If the measured tension is not within the standard range, ask the mechanic to readjust it until it reaches the standard value.

6. Small batch trial production

10 pcs of trial production will be sent to IPQC for project confirmation, and inspection will be available before mass production. During production, the operator must check whether there are adverse phenomena, such as plastic coating and suspension strength. Terminal tension test.

7. 5S after production termination

After production, classify products and wastes, and clean the environment around the machine.

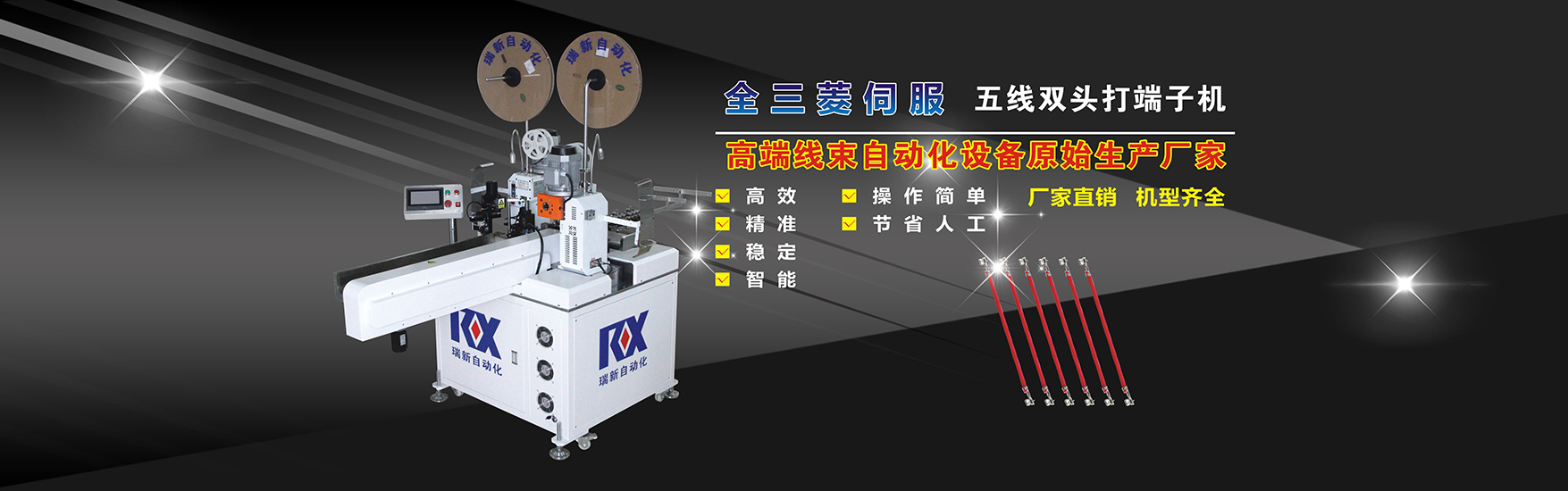

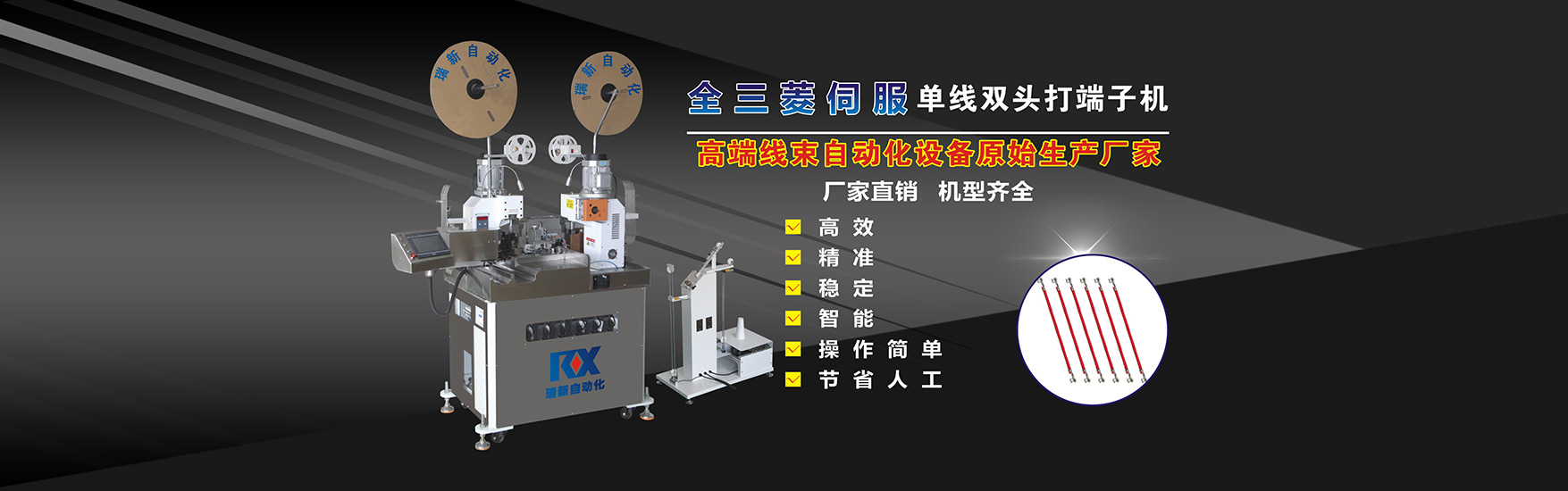

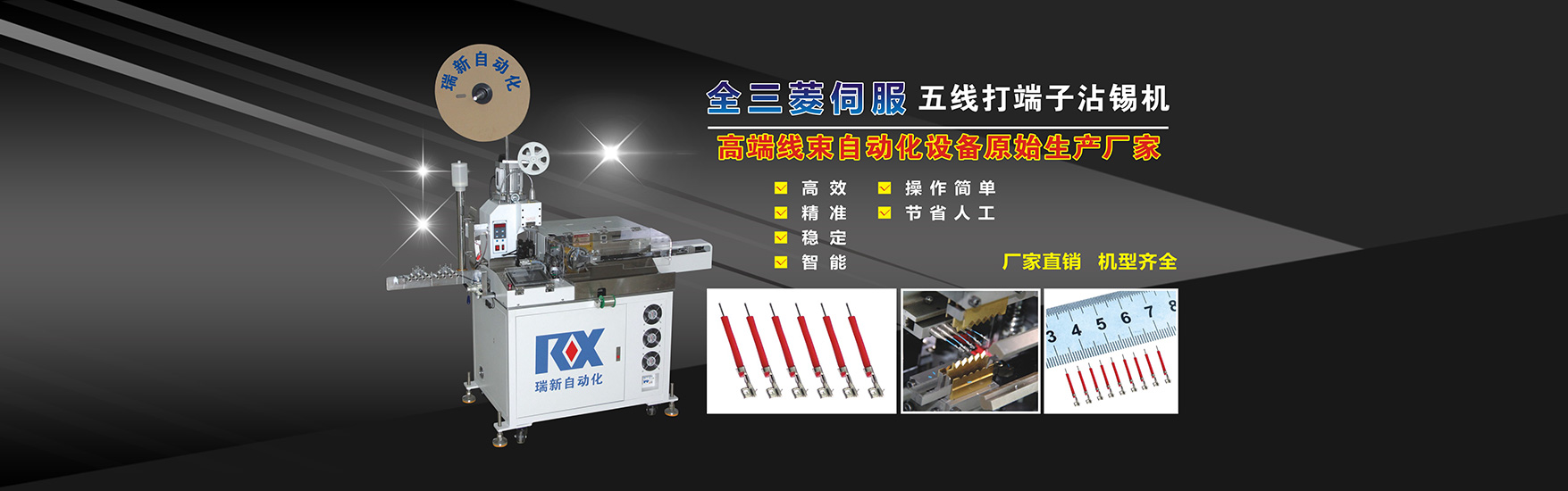

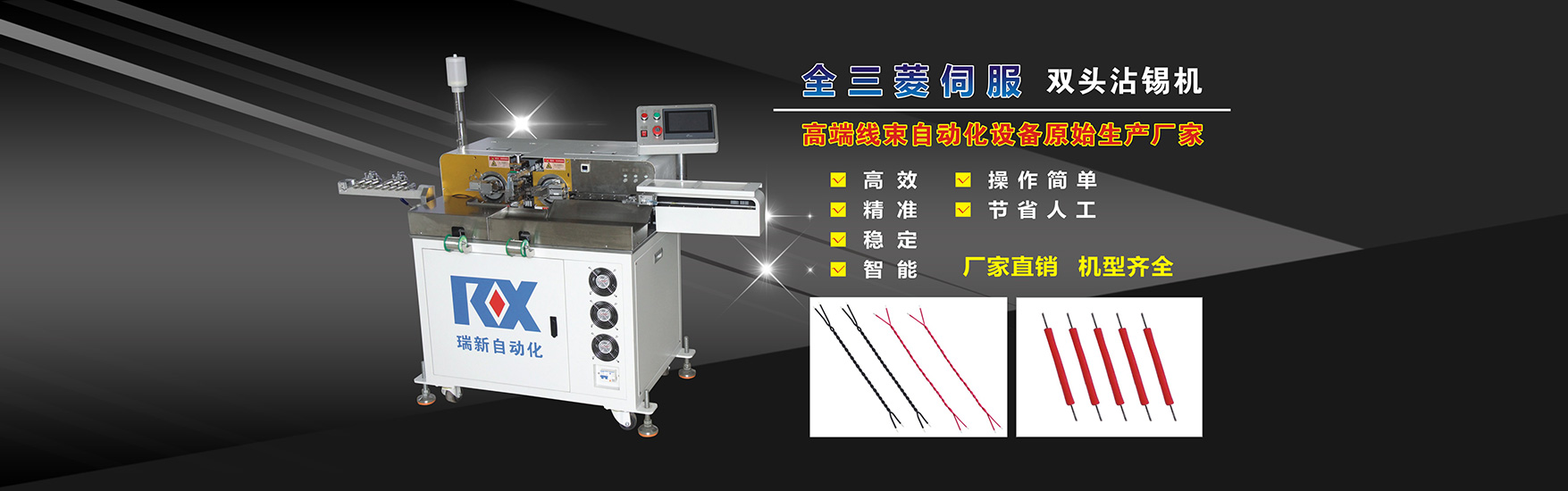

As an important equipment to improve the efficiency of wire harness production and reduce labor cost, the full-automatic terminal machine has many things to pay attention to. Although it is troublesome, it has to be paid attention to. Only in this way can we better complete the operation of the automatic terminal machine and reduce the delay caused by wrong operation. It is also the top priority in production. And for our harness manufacturers, it is necessary to incorporate the above contents into the safety operation procedures of full-automatic terminal machine to make it more standardized. If you do encounter problems in the process of use, please contact our terminal machine automatic terminal machine | full automatic terminal machine | full automatic terminal machine manufacturer | manufacturer Ruixin automation is a high-tech enterprise specializing in R & D and manufacturing automatic harness end processing equipment. The company is located in a prefecture level city under the jurisdiction of economically developed Guangdong Province of China. It has the reputation of "world factory". It is the beginning of modern Chinese history and Dongguan, one of the "Four Tigers of Guangdong". After decades of development and technical precipitation, the company has domestic advanced production equipment and perfect management system, and has won the trust and support of many customers at home and abroad with excellence quality and good reputation.