There is a clear comparison between single head terminal machine and double head terminal machine. As the name implies, we can know the difference between the two appearances. The double head terminal machine sounds like it has one more head than the single head terminal machine. In this way, the double head terminal machine is definitely better than the single head terminal machine, and the work efficiency is definitely advantageous. But it is not the only advantage. Now, Ruixing will take you to have a detailed understanding, There is a sharp contrast between the single head and the double head of the terminal machine.

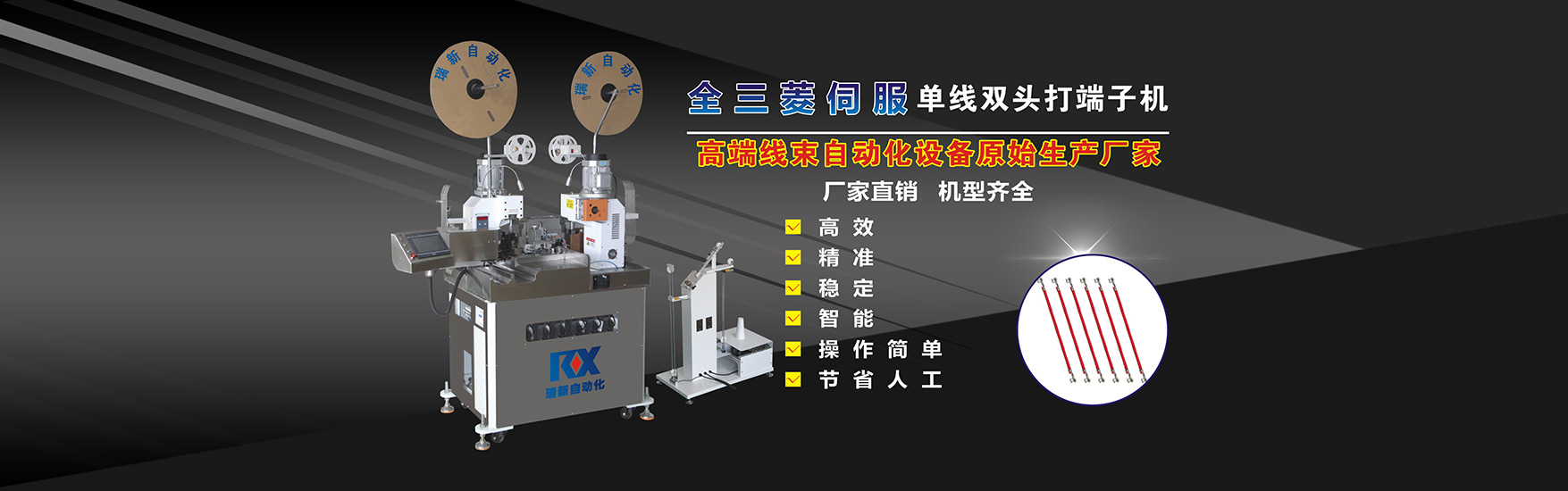

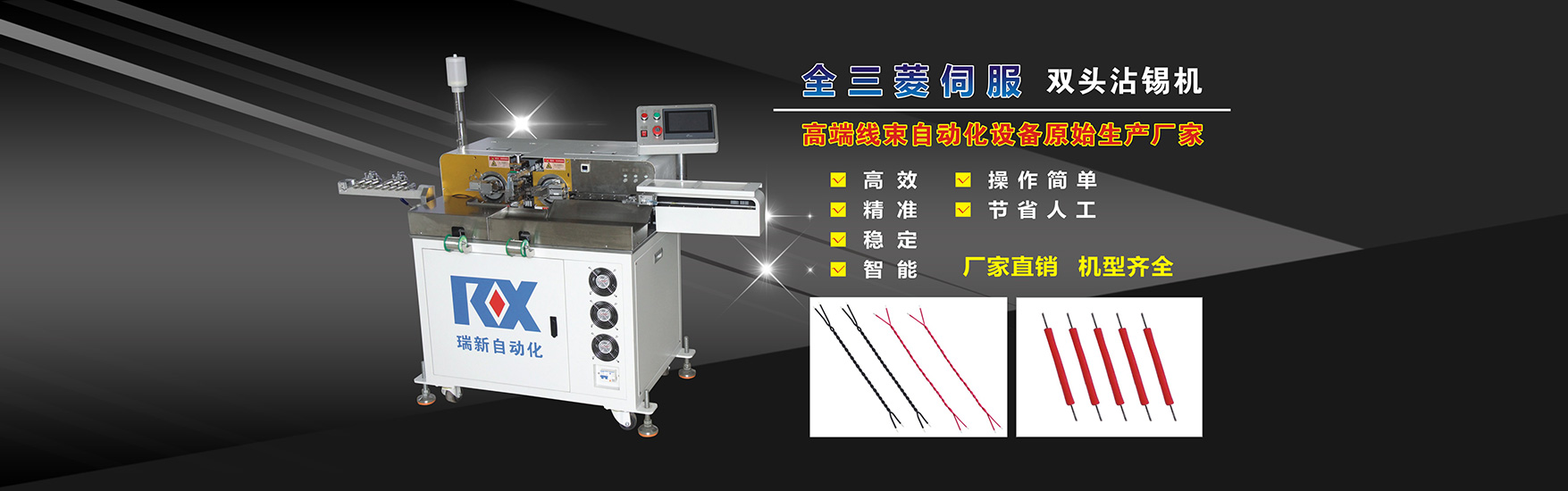

1: Single terminal machine

The operation can only be carried out at a single head, with high practicability and simple operation, as follows:

1. Tin dipping wire 90 ° vertical tin dipping, full dip and point dip, even tin dipping; The heating tube of the tin furnace is easy to replace, and can be taken out directly when cleaning is required, which is convenient for maintenance.

2. The equipment adopts high-precision ball screw, and the tangent accuracy can reach 0.01mm

3. Automatic crimping whole process pressure monitoring, crimping failure alarm, automatic screening and adoption, terminal crimping appearance CCD detection, and defective products are automatically discharged;

4. Monitoring the plugging force of the rubber shell, the plugging force can be set according to the size of the wire, and the defective products can be automatically discharged;

5. The replacement of the rubber shell threading mechanism is modular. The rubber shell with the same pin distance can be produced by simply adjusting two adjustment blocks. The rubber shell with different pin distance can be produced by replacing the whole set of rubber shell threading mechanisms. The replacement is simple and the efficiency is improved.

6. The rubber shell insertion machine adopts the computer operation interface to conduct full-automatic pull-out force detection for the terminal, and can issue the terminal pull-out force curve analysis report; Equipped with ultra-high definition vision system, it can realize real-time image display, comparison and analysis of products. In case of poor crimping, it will give an alarm and automatically screen out defective products. This design greatly saves labor cost, ensures product quality and improves production efficiency.

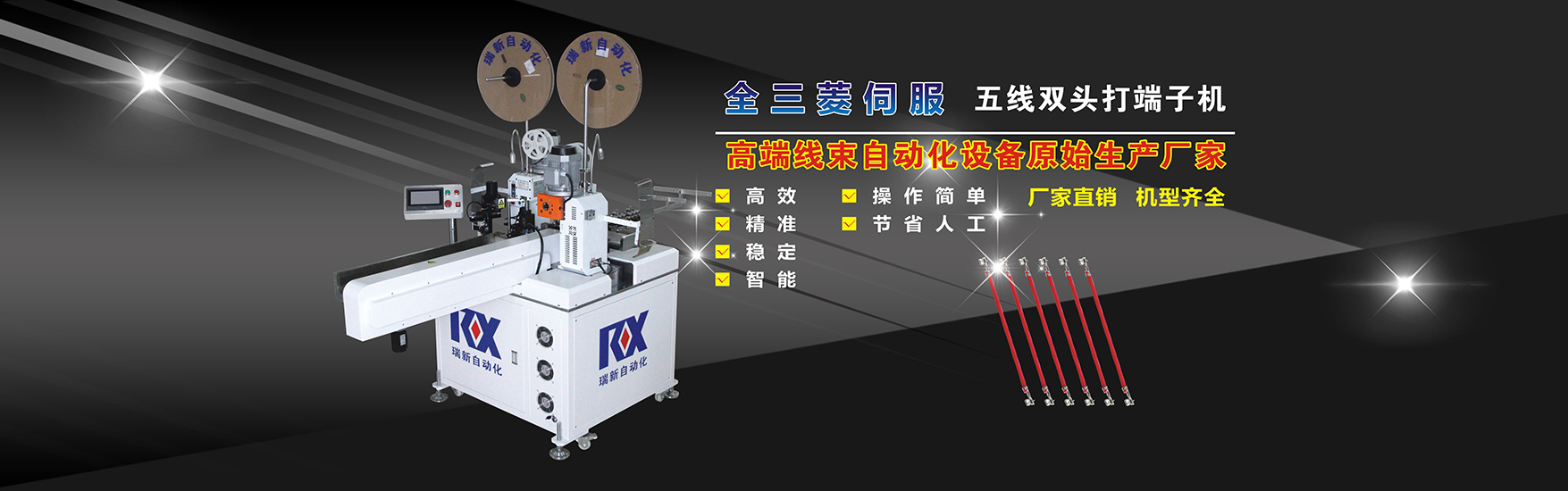

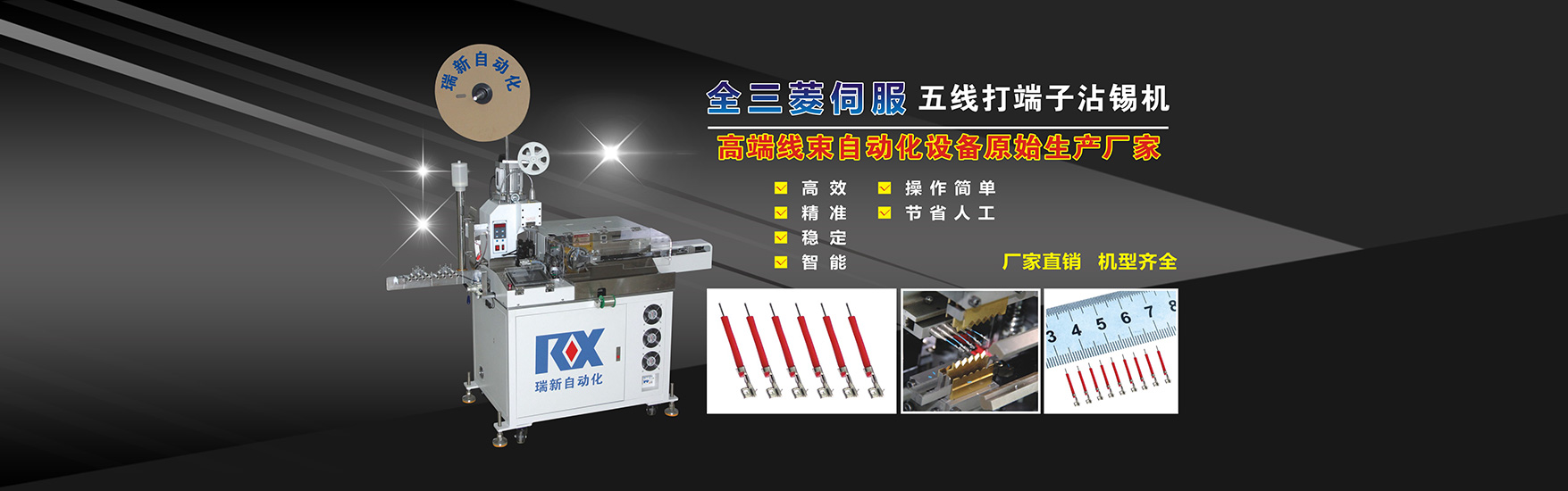

2: Double end terminal machine

It can rivet a variety of heterogeneous terminals, which can adapt to more types of operation and have higher work efficiency, which is specifically reflected in:

1. Fully automatic double head wire cutting, stripping, end punching and rear half stripping combine the functions of wire cutting machine and terminal machine, with high precision, fast speed and stable performance.

2. LCD screen, high-definition Chinese interface, simple operation.

3. The whole machine adopts servo control, with high speed and low noise.

4. Full computer touch digital debugging parameters, simple and fast.

5. The detection function is complete, and the wire rod, end beating, air pressure and other machine abnormalities automatically alarm.

6. Novel concept, simple replacement of OTP direct mold, horizontal mold and blade, automatic receiving of terminal waste paper and cutting of terminal waste.

Dongguan Ruixin automation, crimping machine automatic terminal machine | automatic terminal machine manufacturer | automatic tin dipping machine | automatic tin dipping machine manufacturer | full automatic crimping machine | wire harness crimping machine | connector wire harness crimping machine automatic crimping machine Ruixin automation, friends in need are welcome to consult and understand.