I often encounter some problems when I operate the terminal machine. Today, Ruixin automation comes to analyze with us what causes the terminal wire break. After studying the use of the terminal wire, it is found that the reasons for the terminal wire breaking are in the following aspects.

1. Some of the used structures are unreasonable. Generally, the bending radius of the terminal wires is very small. In some harsh environments, the requirements will be greatly increased. If the structure is unreasonable, the terminal wires may be broken. All shall be used correctly and reasonably.

2. The material properties of the insulation layer and sheath layer of the terminal wire are different from those of foreign materials. In terms of structure and material physical properties, there are many differences from high-quality terminal wires, and the materials are also different. When selecting materials, you must not be greedy for cheap, and use materials reasonably. For the products used, inferior materials may also lead to the fracture of the terminal wire.

3. There are differences in the processing technology of each place. At present, there are great differences in the terminal wire processing level and parameters in the market. The processing equipment level of some small processing plants is not up to the standard, which leads to the quality not being guaranteed and the terminal wire breaking in subsequent use.

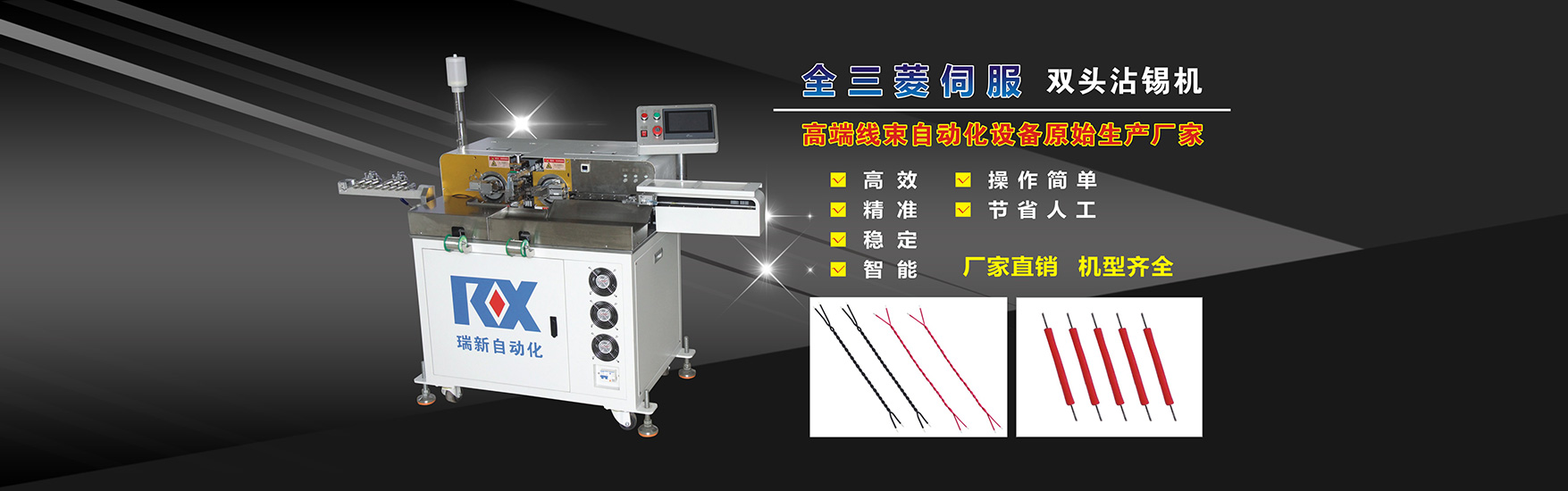

Dongguan automatic terminal machine | automatic terminal machine manufacturer | automatic tin dipping machine | automatic tin dipping machine manufacturer | terminal machine | full automatic terminal machine tin dipping machine Ruixin automation all operation methods of these equipment Ruixin automation has