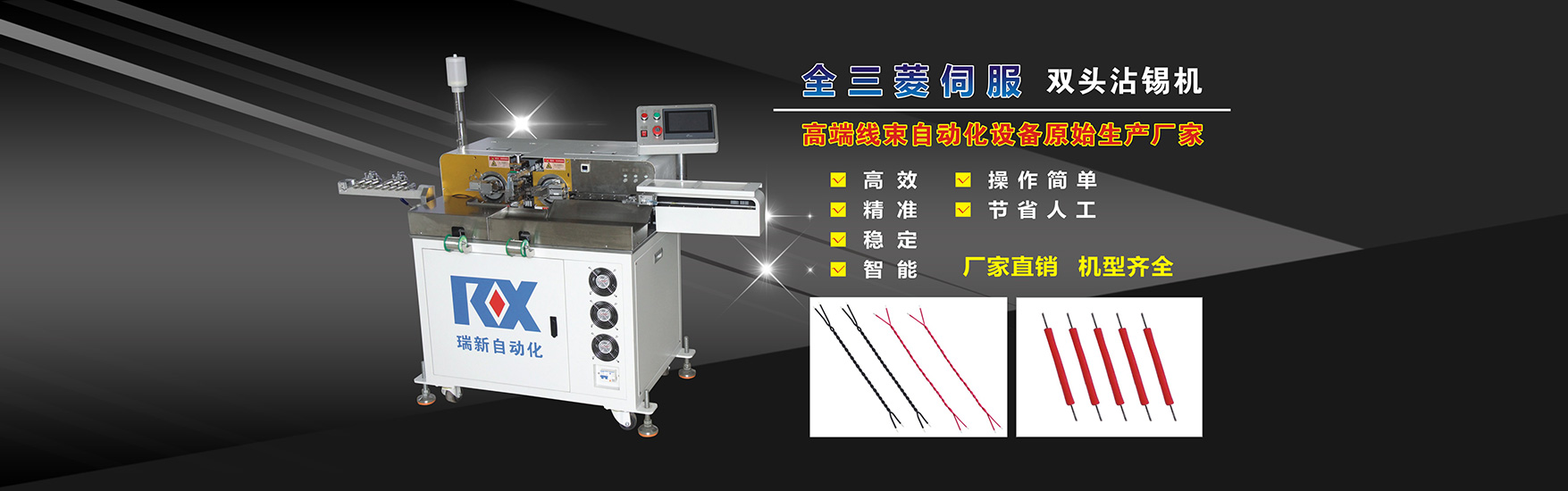

Dongguan | Ruixin automation equipment Co., Ltd. is devoted to the research and development of new products of full-automatic double head twisted wire tin dipping machine. Compared with the previous products, it has new technologies in all aspects of operation, with an hourly production capacity of 12000 and ultra short line performance of up to 10mm.

Description of product features:

1. Computer knife adjustment, no need to pad the blade, simple and convenient operation, high precision.

2. Operation screen Kinco 7-inch full Chinese version, easy to understand, one person can operate

3. Pneumatic components: adek, German brand FESTO

4. Thermometer: OMRON

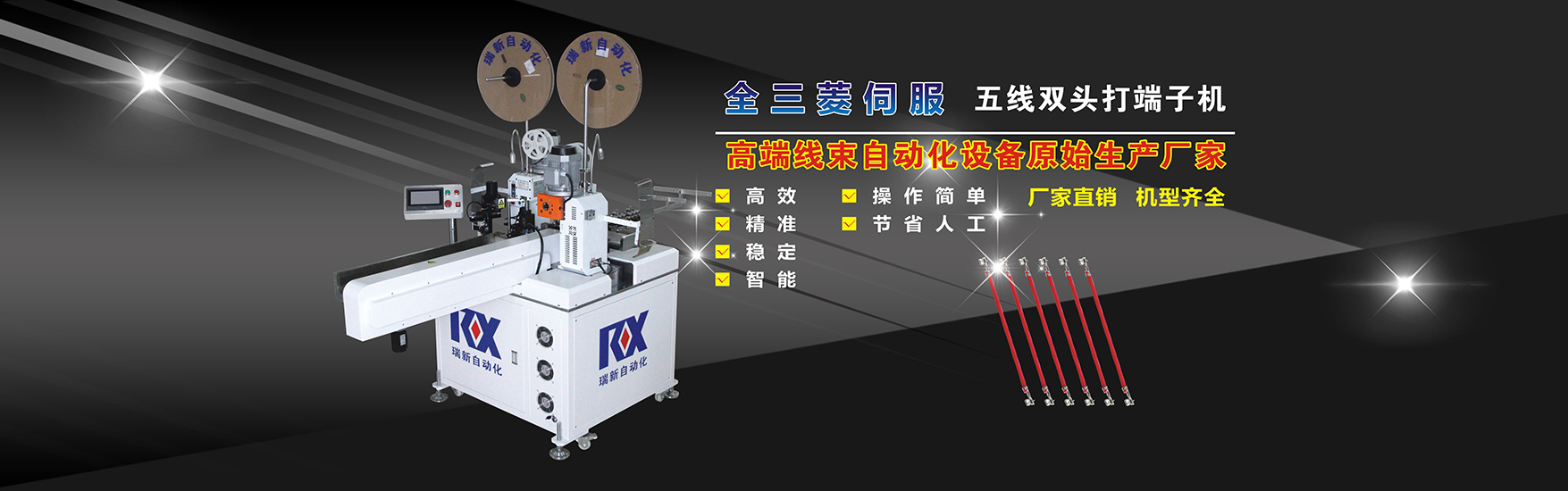

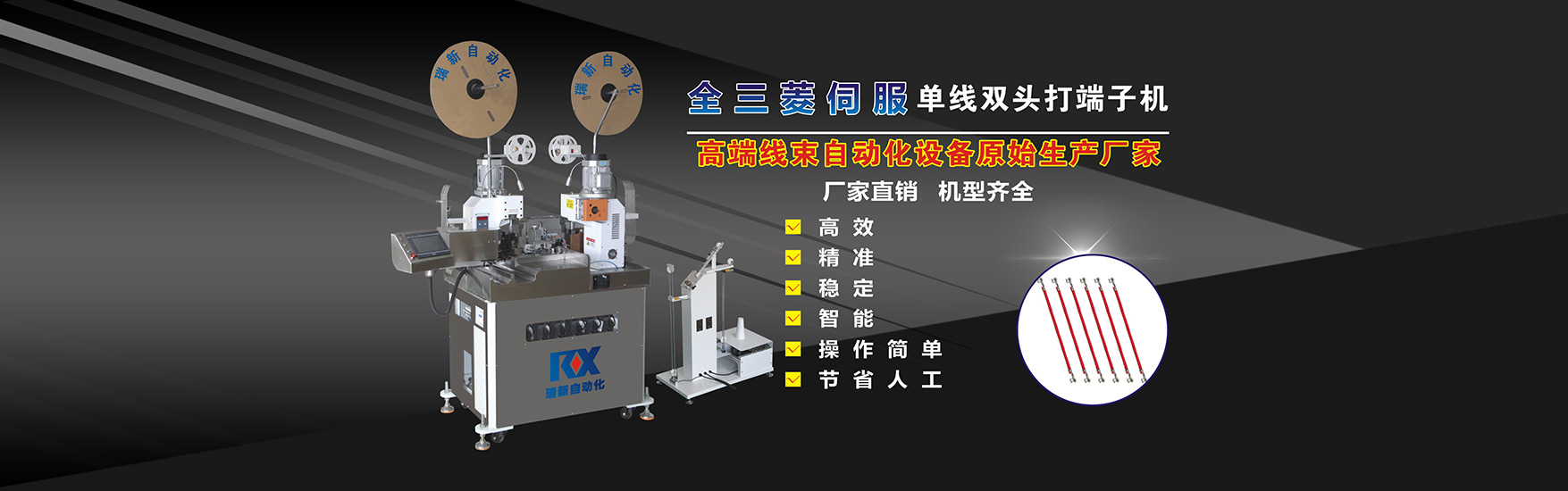

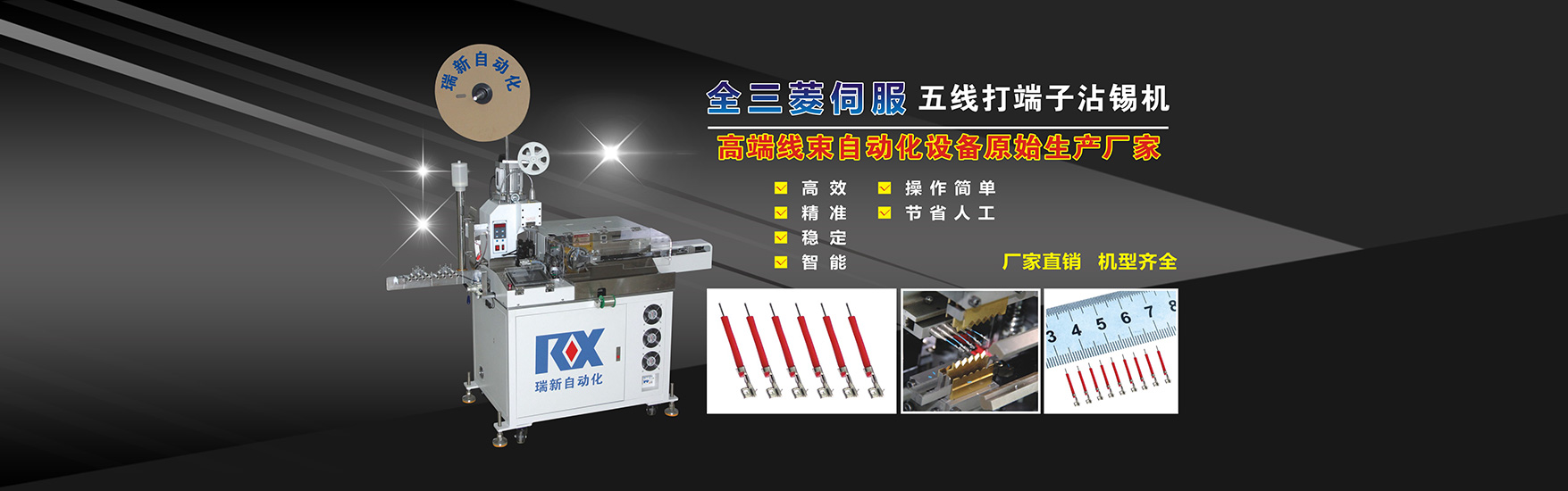

5. Motor: Mitsubishi servo, accurate, efficient and stable

6. Screw rod, guide rail: Taiwan Shangyin

7. Digital display air pressure detection

8. Touch screen touch control method is adopted for adjustment, including: wire length, opening length, half stripping length, twist wire tension, twist wire length, tin dipping length, etc. one key completion

9. It adopts computer-based automatic detection, low air pressure, abnormal motor, abnormal belt, etc. when abnormal, it can automatically stop the machine and display the cause of the fault, so as to facilitate and quickly troubleshooting

Summary: the product performance has been greatly improved. The whole machine adopts high-quality imported raw materials to reduce the risk of machine failure. The operation is simple and easy to understand. The technical adjustment is simple and the adjustment time is short, which can greatly reduce the adjustment time.

Crimping machine automatic terminal machine | automatic terminal machine manufacturer | automatic tin dipping machine | automatic tin dipping machine manufacturer | full automatic crimping machine | wire harness crimping machine | connector wire harness crimping machine automatic crimping machine Ruixin automation